First let me say that I am by no means an expert, but I have some experience with flip keys and thought I’d share my experiences to help those who are looking to take the plunge.

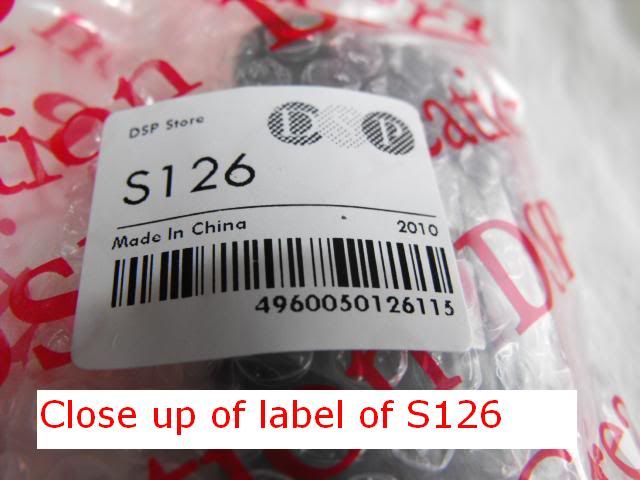

Flip keys for Hyundais seem to be quite popular on auction sites. I’ve really only dealt with one vendor, so I do not have any opinions about other brands/stores.

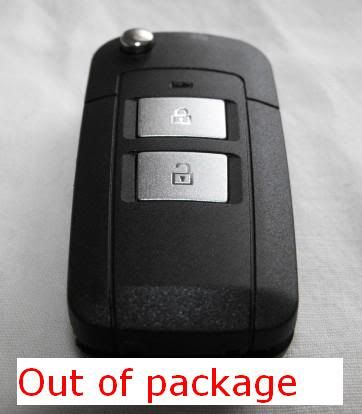

The flip key style I will highlight is the model with two buttons. My Hyundai Accent OEM fob actually has three buttons, but I decided to hide the panic button because of the lack of a model with a panic button AND a battery holder. Personally I think the flip key looks a bit cleaner and the battery holder is very convenient to install.

The following pics are meant to serve as a pictorial for forum users who are interested in learning more about this simple (for some!) conversion to enhance their ownership experience.

In Canada our keys have ignition chips, and so one must access the chip to place in the flip key module. Those in the USA simply need to use a good copy of their key and insert their fob inside. Pics are from different models, in case those eagle-eyed readers spot differences.

I do not work for these companies nor do I wish to make a profit for them. This is simply my contribution to forum users in the quest for information.

You may notice my emphasis on using a good quality (ILCO) copy of your key. A professional key cutter in my area has allowed me to share these points about keys. Thanks for your contribution, Jason. DO NOT USE THE INCLUDED BLANKS! Here’s why:

“There is a big difference between Korean/Chinese-made keys and USA-made keys: one of the main differences lies in the hardness of the Korean/Chinese keys due to the lower amount of Zinc. These Chinese and Korean Keys are much harder and may wear out the key ignition lock cylinders faster than USA-made standard keys. So basically, Korean/Chinese-made keys (themselves) wear less but the wear on the ignition cylinder in your cars using these Eastern keys would be faster. The wear of ignition lock cylinders may likely cause problems down the line.”

“A thing which makes difference in cutting the keys is its hardness. ILCO, (the largest key manufacturer of North America) after melting the brass for their keys, zinc is added to make the metal a little softer (but to the level not to compromise on the quality of metal to make a key) to ease cutting the key properly. My experience leads me to guess that the Chinese or Korean-made after market keys are made without adding the zinc (to cut on costs), that's why several times, with the key being too hard, it just shoots out of the mount on the key machine. Keys for Honda and Lexus (side winder cut keys commonly known as laser cut keys) from Chinese origin have serious problems in cutting, being more harder than OEM keys and several times have broken my cutter blade while working on these.”

“… I decided to let forum members know the difference between Korean and USA made keys, why Korean-made keys are not cut right, etc. I have been doing research on this issue of the problem with Kia Forte Keys from Korea. I found out that the major difference why there is a problem in cutting the key is its width (cut side measurement). The Korean keys which come with the flip shell have the width of 8.35 mm while the USA-made keys are almost 8.7 mm wide. This difference in width makes a key cutters job from difficult to near impossible.”

“Another difference in these two type of keys which I just noticed this morning is the depth of grooves in the key. The grooves on Korean keys are deeper than the USA keys.”

“The final difference between these keys is the weight. The Korean keys weigh between 5.9 and 6.0 g while the US ones (the USA-made key was machined to the exact dimensions of the Korean key to fit into flip shell) weigh 6.9 g.”

There you go – I’m convinced…

So here you go with my pictorial on the flip key for our cars – I’m sure you could apply the pics to other models. Please post any of your own pics or questions, and we’ll try to help each other out.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Flip keys for Hyundais seem to be quite popular on auction sites. I’ve really only dealt with one vendor, so I do not have any opinions about other brands/stores.

The flip key style I will highlight is the model with two buttons. My Hyundai Accent OEM fob actually has three buttons, but I decided to hide the panic button because of the lack of a model with a panic button AND a battery holder. Personally I think the flip key looks a bit cleaner and the battery holder is very convenient to install.

The following pics are meant to serve as a pictorial for forum users who are interested in learning more about this simple (for some!) conversion to enhance their ownership experience.

In Canada our keys have ignition chips, and so one must access the chip to place in the flip key module. Those in the USA simply need to use a good copy of their key and insert their fob inside. Pics are from different models, in case those eagle-eyed readers spot differences.

I do not work for these companies nor do I wish to make a profit for them. This is simply my contribution to forum users in the quest for information.

You may notice my emphasis on using a good quality (ILCO) copy of your key. A professional key cutter in my area has allowed me to share these points about keys. Thanks for your contribution, Jason. DO NOT USE THE INCLUDED BLANKS! Here’s why:

“There is a big difference between Korean/Chinese-made keys and USA-made keys: one of the main differences lies in the hardness of the Korean/Chinese keys due to the lower amount of Zinc. These Chinese and Korean Keys are much harder and may wear out the key ignition lock cylinders faster than USA-made standard keys. So basically, Korean/Chinese-made keys (themselves) wear less but the wear on the ignition cylinder in your cars using these Eastern keys would be faster. The wear of ignition lock cylinders may likely cause problems down the line.”

“A thing which makes difference in cutting the keys is its hardness. ILCO, (the largest key manufacturer of North America) after melting the brass for their keys, zinc is added to make the metal a little softer (but to the level not to compromise on the quality of metal to make a key) to ease cutting the key properly. My experience leads me to guess that the Chinese or Korean-made after market keys are made without adding the zinc (to cut on costs), that's why several times, with the key being too hard, it just shoots out of the mount on the key machine. Keys for Honda and Lexus (side winder cut keys commonly known as laser cut keys) from Chinese origin have serious problems in cutting, being more harder than OEM keys and several times have broken my cutter blade while working on these.”

“… I decided to let forum members know the difference between Korean and USA made keys, why Korean-made keys are not cut right, etc. I have been doing research on this issue of the problem with Kia Forte Keys from Korea. I found out that the major difference why there is a problem in cutting the key is its width (cut side measurement). The Korean keys which come with the flip shell have the width of 8.35 mm while the USA-made keys are almost 8.7 mm wide. This difference in width makes a key cutters job from difficult to near impossible.”

“Another difference in these two type of keys which I just noticed this morning is the depth of grooves in the key. The grooves on Korean keys are deeper than the USA keys.”

“The final difference between these keys is the weight. The Korean keys weigh between 5.9 and 6.0 g while the US ones (the USA-made key was machined to the exact dimensions of the Korean key to fit into flip shell) weigh 6.9 g.”

There you go – I’m convinced…

So here you go with my pictorial on the flip key for our cars – I’m sure you could apply the pics to other models. Please post any of your own pics or questions, and we’ll try to help each other out.